Ductless Fume Hoods

Top Air Systems offers top-of-the-line ductless fume hoods that provide the needed protection from harmful and toxic chemicals.

Our ductless fume hoods have built-in airflows across the workstation, exhausting out the contaminated air away from you and recycling them back as clean air. Our ductless fume hoods are safe and convenient to use, and they boast sophisticated features that help you save energy. We have different configurations to choose from, including all-around clear glass and downflow units.

What’s a Ductless Fume Hood?

A ductless fume hood is contained ventilation equipment or working space that filters out chemical airborne materials and recycles them back to the working environment as breathable air. It uses activated carbon filters to clean the fumes. Ductless fume hoods usually have a frontal airflow to get the air out at a controlled rate to prevent the harmful gases from going out of the workstation.

How Does it Work?

There are two filters in a ductless fume hood – the pre-filter and the main filter. Both of them work to remove the contaminants in the fumes. It starts with the ambient air going into the ventilation hood with the gases or vapors produced during the laboratory work. The air in the hood goes through the pre-filter, where some of the impurities are sifted.

Once it has gone through the pre-filter, it goes through the main filters, where other particulates are thoroughly removed. Then, the air goes out from the main filter to the workstation as breathable air.

Common Applications

Ductless fume hoods are used in various fields. Some of the most common applications are the following:

- Life Sciences

- Forensics, Fingerprinting and DNA

- Educational Purposes

- Clinics and Hospitals

- Dental Laboratory

- Cleanrooms

- 3D Printing

- Archaeology

- Glass Manufacturing

- Mycology

- Soldering

- Pharmaceutical

- Art Restoration

- Production of Glues, Paints, and Solvents

What to Consider in Choosing a Ductless Fume Hood?

In choosing a ductless fume hood, you have to consider the following factors:

- How do you intend to use it? Some ductless fume hoods are designed for light-duty applications or to process specific gases. Other units are built for heavy-duty processes and chemical filtration.

- Are you working with chemicals that can be filtered with the fume hood’s available carbon filters? Apparently, some chemicals or substances can’t be safely or effectively sifted if you’re only using a ductless fume hood.

- Is your working place sufficient enough to run ductless fume hoods? Using the ductless fume hood to process air consumes a lot of energy, so you have to make sure that you can afford to manage the large energy consumption and running costs.

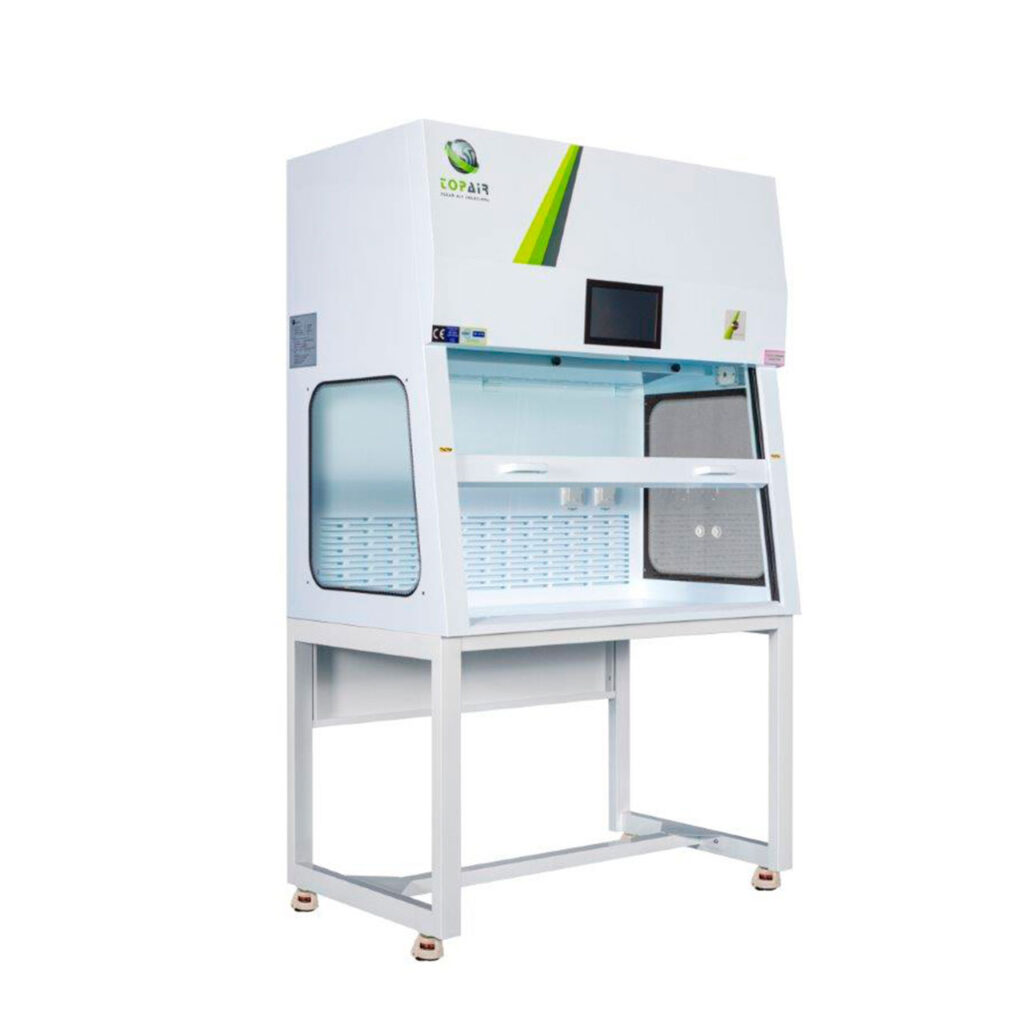

Polypropylene – Basic

The Basic Polypropylene Ductless Fume Hood provides a safe environment for working with harsh chemicals like organic solvents. It comes with an air velocity display, a seven-inch colored touchscreen, a 10-speed fan, an hour counter, and a filter replacement alarm for carbon filters. Clients can customize this unit according to their preferences.

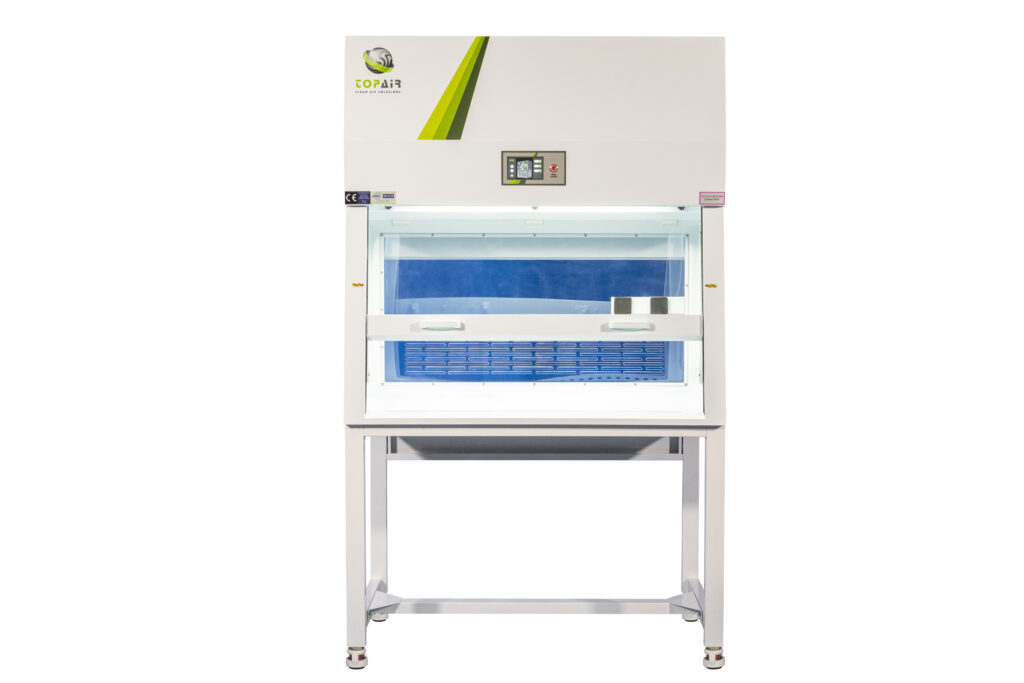

Polypropylene – Pro

The advanced version of the basic unit is the Pro Polypropylene Ductless Fume Hood. It includes a variable air volume (VAV) system, which measures the air velocity. It is built with a nine-inch touchscreen, temperature and humidity sensor, chemical sensor alarm, and a red light alarm that is activated when an error is detected.

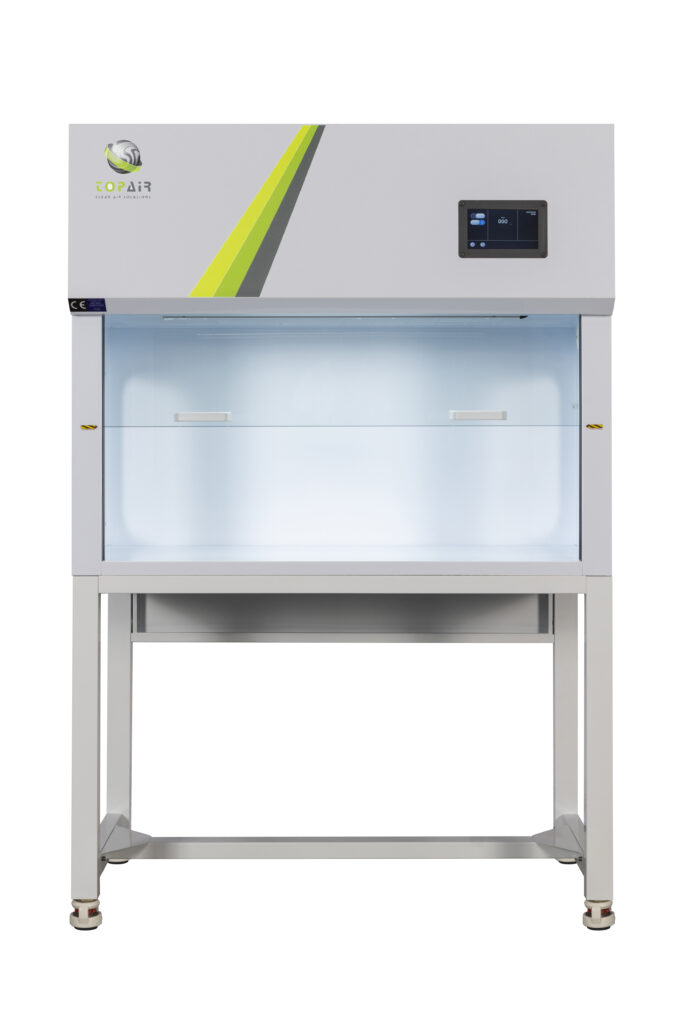

Educational With All-Around Clear Glass

From the name itself, this Topair Ductless Fume Hood model comes with a clear glass that provides 360-degree transparency. It is an exceptional choice for educational presentations due to its all-around visibility. It also has a seven-inch touchscreen display, a tempered glass front window, a quiet EC fan, and cost-effective, environment-friendly LED lighting.

Education Inverted All-Around Clear Glass

This model is also made with 360-degree transparent glass, which makes any working experiment visible to anyone. It is built with a five-inch colored touchscreen that displays the controls and functions. It also has several outstanding features, including a 10-speed fan, an EC fan, 800 LUV LED lighting, and easy front access for replacing filters.

Weighing Station

It is designed for weighing substances like powders and other forms of chemicals. Some of its features include a five-inch touchscreen colored display, a 10-speed fan, an hour filter counter, and a filter replacement alarm.

Ecoline

The Ecoline consists of a compact, cost-effective benchtop fume hood and a polycarbonate front window. Its structure is made of polypropylene, which highly resistant to chemicals. It has a five-inch colored touchscreen to control the power and lighting of the equipment, a 10-speed fan, and back access for replacing filters.

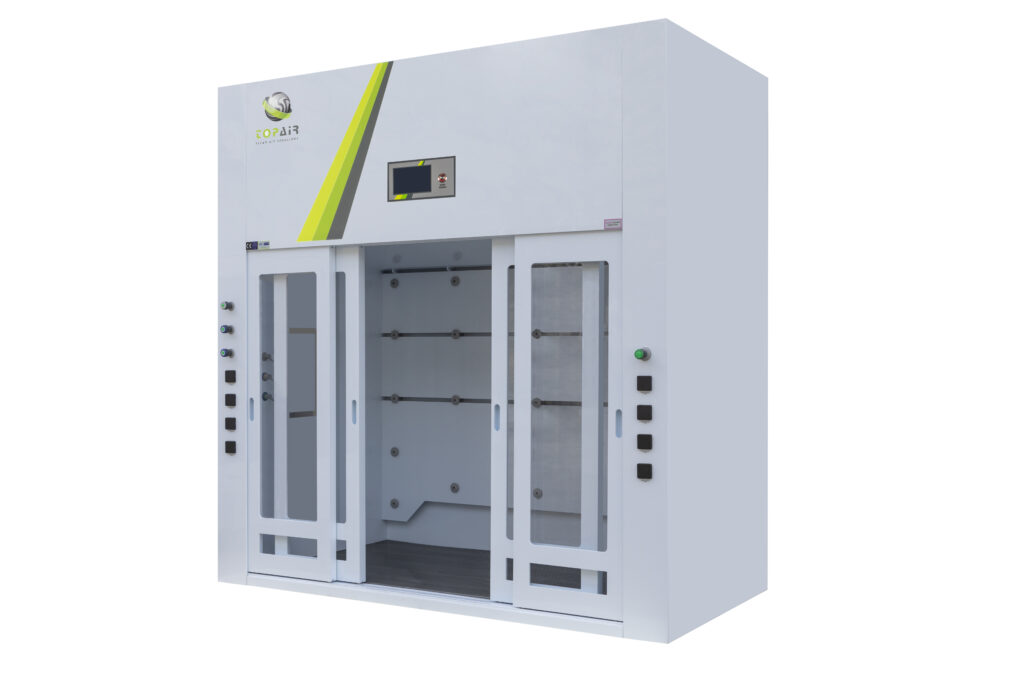

Downflow Unit

This is a standalone, ductless workstation that protects against fumes and harmful chemicals. It is an open structure for clear visibility and close inspection. Because it is a Downflow unit, the particles flow downward and go through several filters to remove the contaminants. The digital control system allows users to control the power, lighting, and fan speed.